PRODUCT

صفحة رئيسية>منتجات>

crusher plant maintenance articles

Construction Working and Maintenance of Crushers for Crushing

Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article. Crushing Technology. There are four 2014年2月25日 A cone crusher is used in mineral processing plant as a secondary or tertiary type rock crusher. In this case study, explored the general objective of the failure Reliability centered maintenance of cone crusher: a case study2022年4月26日 The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while (PDF) Optimization Capabilities for Crushing Plants - ResearchGate

(PDF) Crushing and Screening Handbook - Academia

The present paper also considers the operational, instrumental, mechanical and maintenance aspects of crushing plant, focusing on the capacity and quality. 2018年3月15日 Implementing a preventive maintenance program is the best method of keeping a crusher in good operating condition for a long period. Preventive maintenance will include scheduled checks, Understanding three different types of crusher The purpose of the research presented in this paper is to explore the process design of crushing plants in order to gain further understanding on how the crushing plant CRUSHING PLANT PROCESS OPTIMISATION

Optimization Capabilities for Crushing Plants - Chalmers

The objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective The Reliability of the crusher influences the productivity of the plant. The purpose of this paper is to focus the application of reliability centered maintenance with an aim to Reliability centered maintenance of cone crusher: a case study> Provide an overview of the needs for optimization capabilities in crushing plants. > Introduce the area of research and the scope for the development of the optimization Optimization Framework for Crushing Plants - Chalmers

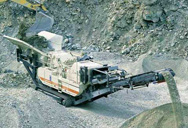

Seven Critical Maintenance Items For Mobile Crushing Plants

2023年10月26日 Crusher Components. The crushers in mobile crushing plants are the core components responsible for reducing raw materials into smaller, manageable sizes. Proper maintenance of these components is essential for consistent and efficient crushing. Maintenance tasks include: Regularly checking for wear and tear on crushers, such as 2023年6月22日 Basic roll crusher maintenance items. Perform the following checks frequently for optimal roll crusher performance: 1. Check roll parallel. 2. Check belt tension and alignment. 3. Clean separator Hammermill and roll crusher maintenance and Crusher maintenance 78 1 concave change box 1, 2 months changes 24 x 2 Minor scheduled maintenance 0 Shift changes 183 10 minutes/shift Total ... Ore characteristics are a critical element in both crusher selection and plant design. Dry ores require greater provisions for dust suppression and collection, ...Crushing Plant Design and Layout Considerations - 911 Metallurgist

A Guide to Mobile Crushing Plants: Types, Components,

2023年2月24日 Regular cleaning of the mobile crushing plant, including the crusher and conveyor, can prevent buildup and ensure that the plant is operating at maximum efficiency. Proper storage: When the mobile crushing plant is not in use, it’s important to store it properly to protect it from the elements and prevent any damage.2023年2月28日 Learn how to choose, operate, and maintain a stone crusher plant with our comprehensive guide. Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case studies of successful operations. Get answers to frequently asked questions and ensure the safety and Crushing it: A Comprehensive Guide to Stone Crusher PlantsThe main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.Crushers - All crusher types for your reduction needs - Metso

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Choosing the right type of primary crusher for your operation depends on several factors, including the maximum size of the material to be crushed, the desired output size, and the capacity of the crusher. Other factors to consider include the hardness and abrasiveness of the material, as well as the cost and maintenance requirements of the ...Crusher Plant Maintenance Pty Ltd 739 followers on LinkedIn. Crusher Plant Maintenance was established in 2009 servicing the mining, construction and quarrying industries and has now grown ...Crusher Plant Maintenance Pty Ltd LinkedIn2019年1月27日 Follow crusher backing maintenance schedule carefully to avoid undue damage to equipment. Every 40 hours, check for leaks and inspect Y strainers. Every month, inspect safety devices and perform an oil analysis. At least once per year (or every 2,000 hours) change all oil.Tips for Crusher Maintenance - Thomasnet

Preventive crusher and screen maintenance - Metso

We got comments from Anthony Ryan, sales manager for McHale Plant Sales, based in Tipperary, Ireland, who says Metso Metrics is very useful for preventative plant maintenance and servicing. “We can predict when a plant service is needed, allowing us to better prepare our engineers.2019年1月2日 Failure of crusher components has considerable influence on the productivity of a crushing plant. In order to improve performance and operational reliability, its critical components are needed to be identified Failure rate analysis of Jaw Crusher: a case studyCrusher automation – ensures consistent and effi cient operation. Improves productivity and product quality while reducing maintenance costs by preventing overload situations. Stationary conveyors – a complete range of belt conveyors. Wide variety of widths, lengths, accessories and options. Various models incor-Crushing and Screening Handbook - AusIMM

Demystifying the Crusher Plant: A Comprehensive Guide to

3 天之前 Crusher Plant Aggregate crushing operation is the process of dealing with and processing non-metallic mineral materials for the construction ... Because of the improved coordination, real-time data analysis, and predictive maintenance made possible by this link, dependability has increased and breakdowns have decreased. Energy ...Metso lifting tools make the maintenance of your crusher easy, safe and more efficient. All of our lifting tools are backed by Metso quality, OEM design and expertise, making them the best choice to lift Metso engineered and supplied crusher wear parts.All Metso lifting tools are thoroughly tested and quality inspected to ensure maximum performance and safety.Crusher maintenance tools - Metso2023年2月23日 Primary considerations: Accessibility, safety, and maintenance are critical factors to consider when designing the layout of an aggregate crushing plant. This includes ensuring that there is adequate access for maintenance and repair work, that the plant is designed with safety in mind, and that maintenance is easy and efficient.The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

Five steps to optimize crusher’s lubrication system - Metso

2018年7月30日 Today, oil analysis has taken its place as an indispensable and valuable element of crusher predictive maintenance. There is only one thing that will wear out the inside of a rock crusher, and that is "dirty lube oil". Clean lube oil is the most important factor affecting the service life of the internal crusher components.2023年2月28日 Granite Crushing Plant; Projects Menu Toggle. ... In this article, we will discuss the primary crusher and secondary crusher, their definitions, functions, and different types. We will also examine how they operate, the mechanical principles involved in their operation, and the maintenance and safety procedures required.Primary Crusher vs. Secondary Crusher: Understanding Their Crusher Plant Maintenance Pty Ltd 722 followers on LinkedIn. Crusher Plant Maintenance was established in 2009 servicing the mining, construction and quarrying industries and has now grown into a global maintenance company servicing clients both nationally and internationally. The growth of the company can be attributed to the teams Crusher Plant Maintenance Pty Ltd LinkedIn

Crushers Plant - SAR

Our dedicated customer support team provides comprehensive assistance, ensuring smooth installation, operation, and maintenance of our crusher plants. We strive to build long-term relationships with our clients and provide ongoing support to help them achieve their production goals. Whether it’s for mining, construction, ...2023年2月7日 For daily maintenance, you should: Keep the equipment clean: Dust and dirt can cause the components to wear faster. ... what is the cost of making gravel crusher plant 600tph ...How to check the stone crusher and daily maintenance?

- النباتات النحاس مصنعين في الصين

- سنگ شکن زره

- تركيا منجم للذهب

- كربيد مطحنة نهاية المغلفة

- منتجات الصين خام الذهب مخروط

- سحق إلى مسحوق ميكرون الحجم

- فائض معدات التعدين في الفلبين

- حساب وسائل طحن مطحنة طحن في الاسمنت

- كسارة فكية في رواندا

- مصانع الأسطوانة في الصين

- دليل التفتيش الكسارة fabried لفة لفة

- التكنولوجيا في الرمال الاصطناعية

- مطحنة مطرقة صغيرة مدفوعة pto

- دلو محطم في ماليزيا

- الموردين مطحنة الحجر الجيري الصين كسارة الفك

- مطحنة عمودية في مصنع الأسمنت sep

- خام النحاس خام الذهب شاشة الاهتزاز

- كسارة الفك للبيع أوروبا

- آلة pulveriser الفحم

- اجدد ماكنات طحن سمسم